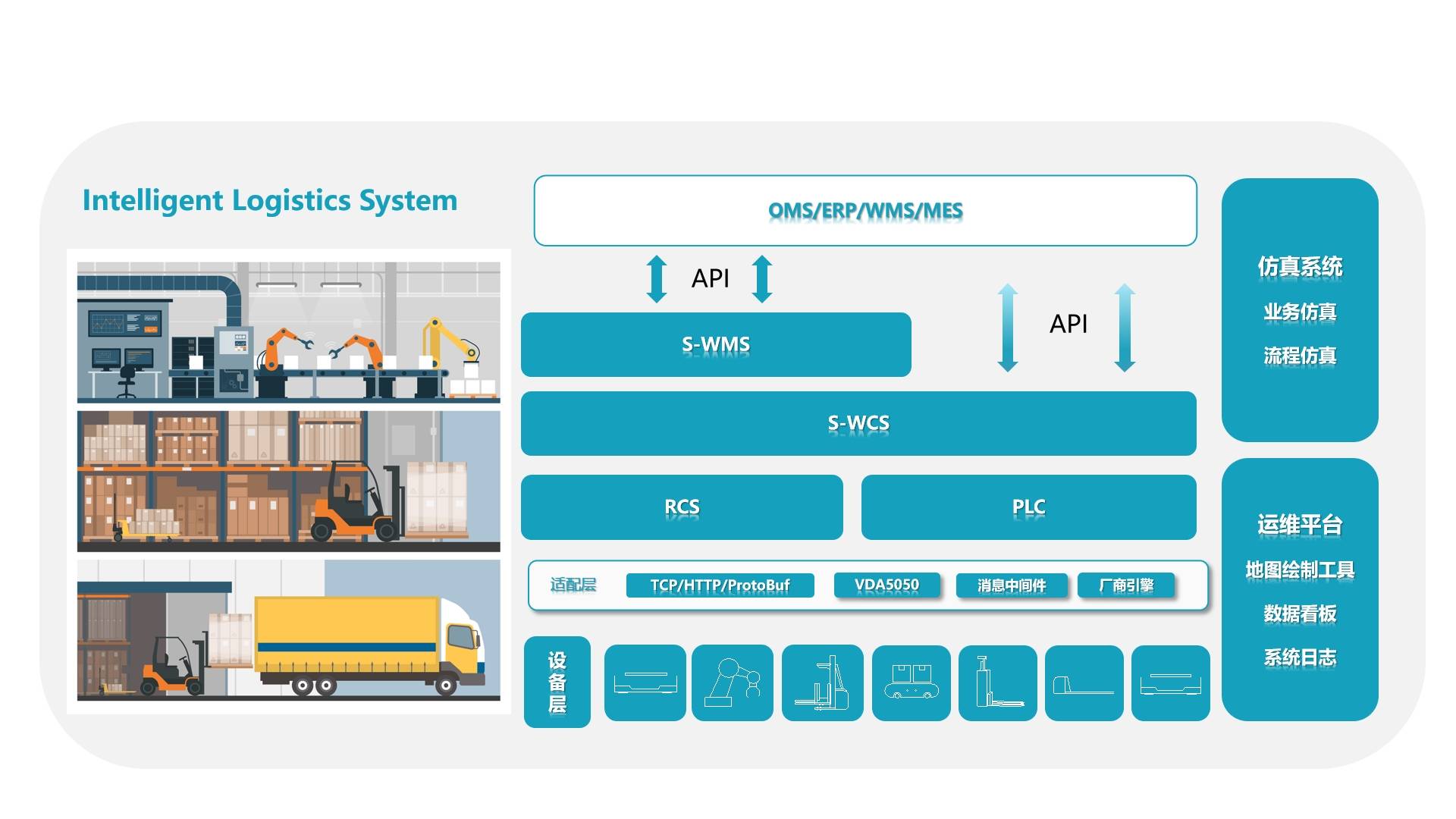

robots; 2) unmanned forklifts, bin robots, hidden fork pallet robots; 3) heavy-duty AGVs, non-standard customized AGVs

AGV/AMR equipment

Picking line side warehouses, finished goods warehouses, etc.

The system realizes high cargo through intelligent mechanical equipment, advanced control system and innovative vertical storage structure.

Effective storage, retrieval and sorting.

Reduction of manual errors

Degree and completeness

XXXX

automated stock dispensing equipment under the landscape.

Mainly used for small item sub-seeding; and

Configure the number and specifications of grids.

Adaptation to different commodities and flows

Classification;

Main characteristics: three-dimensional, flexible,

high quality-price ratio

Creating hand-eye coordination capabilities to free up your hands

No need to enter product information in advance.

Can handle dynamically updated mixes

SKU.

Utilizing our self-developed 3D photo

Machine + Controller, compared to the equivalent

The other brands that are placed are cost effective.

Easy calibration process. Automatic generation

Optimal robot trajectory to avoid obstacles

objects and singularities, eliminating the need for cumbersome displays of

Teach the process.

Simply follow the specified modularization

Robot calibration can be completed. Can

Visualized HMI interface for simple operation

Single friendly.

From flat storage to elevated storage, four-way shuttle intensive storage

Saving land and eliminating errors

Reduced labor intensity, improved management and operator safety

Reduced storage and transportation losses

Effective reduction of liquidity backlog

Enables dense storage

AGV/AMR

Kiva, slam-Kiva, slam-earth cow, tumbler robots

Unmanned forklifts, bin robots, hidden fork pallet robots

Heavy duty AGV, non-standard customized AGVs

xxxxxxxxxxxxxxxxxxxx

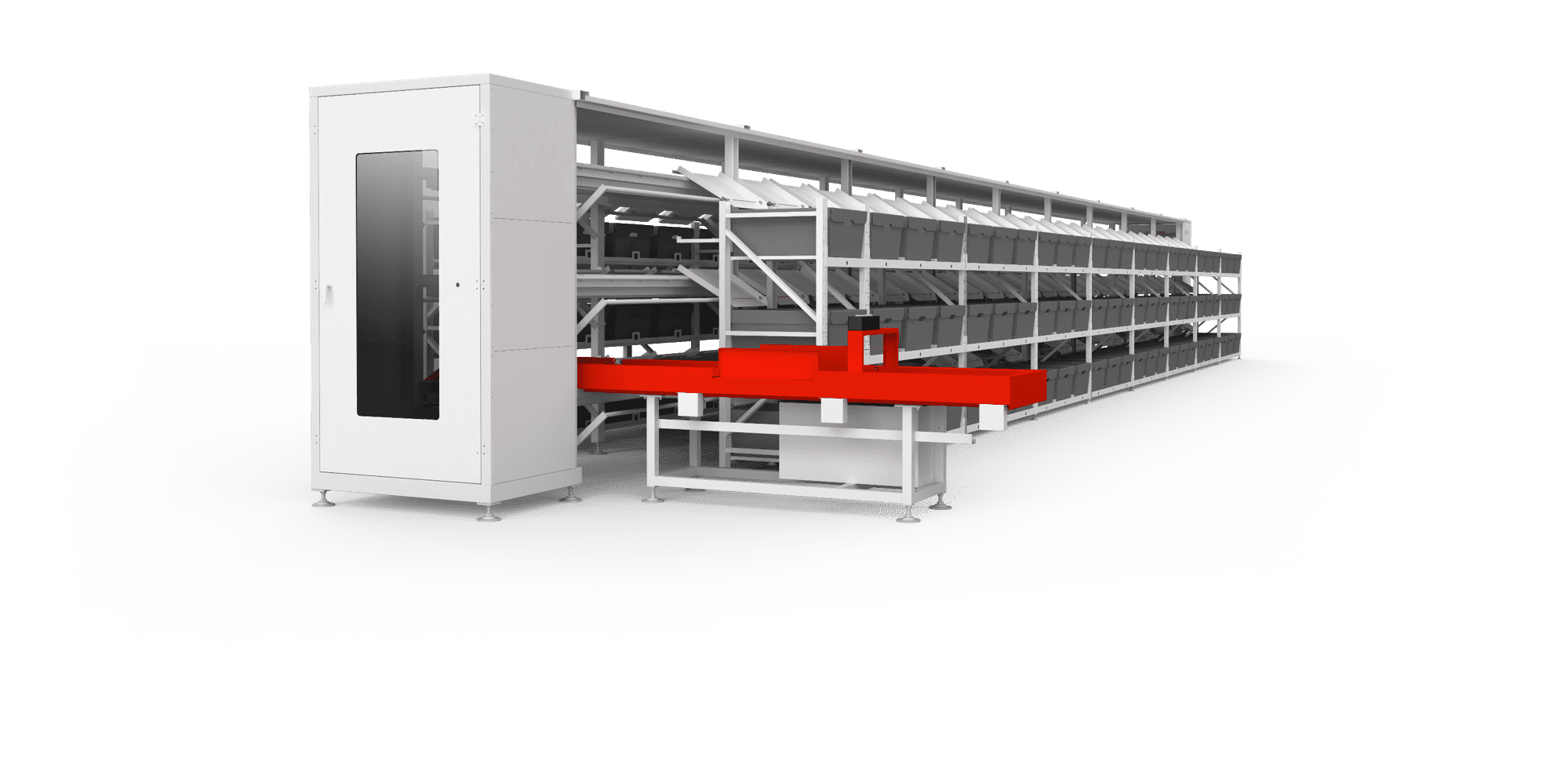

Distribution equipment

Is a support for multi-category, multi-flow scenarios in the automatic distribution of goods equipment, mainly used for small items of goods sub-seeding.

Adopt modular design, flexible configuration of the number of compartments and specifications, to adapt to different commodities and flow classification.

Jingdong Logistics is completely independent research and development, the main characteristics: three-dimensional, flexible, cost-effective;.

robot arm

Easy to deploy: no need to enter product information in advance and can handle dynamically updated mixed SKUs.

Cost-effective: Utilizing our self-developed 3D camera + controller, it is cost-effective compared to other brands with the same configuration.

Simple operation: simply follow the specified modularization to complete the robot calibration. Visualized HMI interface, easy and friendly operation.

Ease of use: easy calibration process. Automatically generates the optimal robot trajectory, avoiding obstacles and singularities, eliminating the need for a tedious teaching process.

storehouse

Both have the dense characteristics of through racking, and can realize the need for automated control. For the forklift requirements are relatively low, than the pressure type and gravity type racking storage density is higher, according to the actual situation can be flexibly selected first-in-first-out or first-in-last-out function. And because of its transportation of goods to achieve automation, very suitable for cold storage and other extreme conditions of the warehouse, in order to reduce personnel activities, improve personnel efficiency and operational safety.

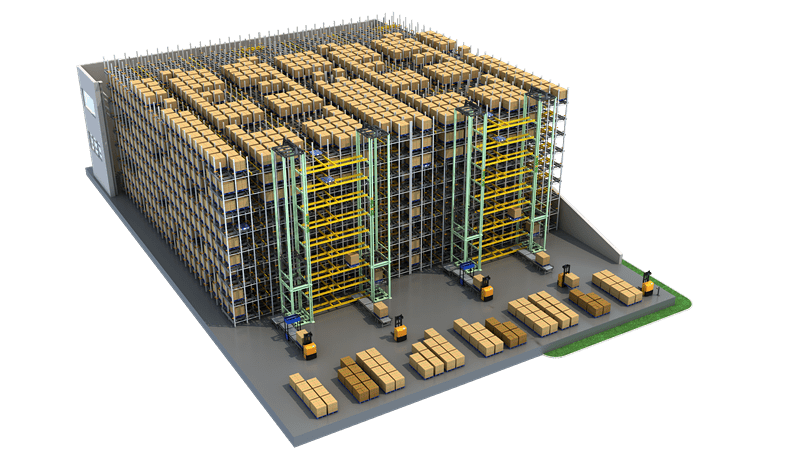

Automated three-dimensional warehouse

With land saving, eliminating errors, reducing labor intensity, eliminating errors, improving management and operator safety, reducing storage and transportation losses, effectively reducing the backlog of liquidity, etc. can be realized intensive storage. It is a widely used storage method at present.